The implementation phase of the HyFuelUp plant is now officially underway, marked by a major early achievement: The arrival of the heat exchangers for the methanation unit.

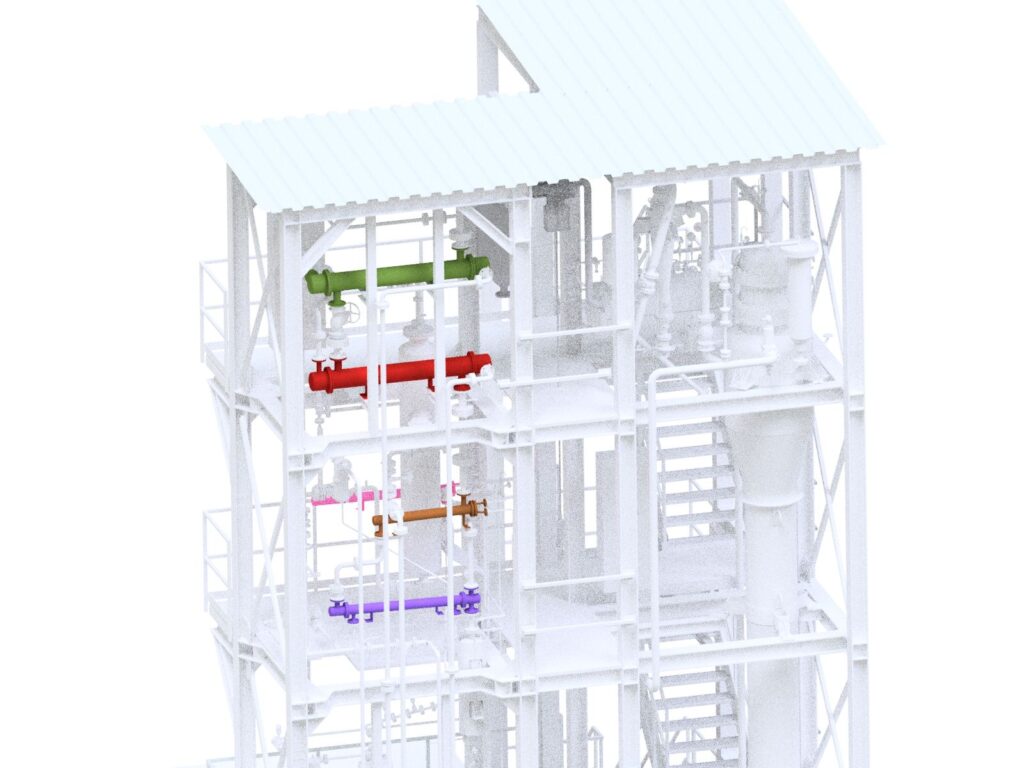

These components are essential to the plant’s thermal management system — the part that keeps everything running at the right temperature. Good thermal control is far from a minor detail; it directly boosts efficiency, increases overall energy yield, and helps keep operating costs in check. In other words, it plays a decisive role in the plant’s economic viability.

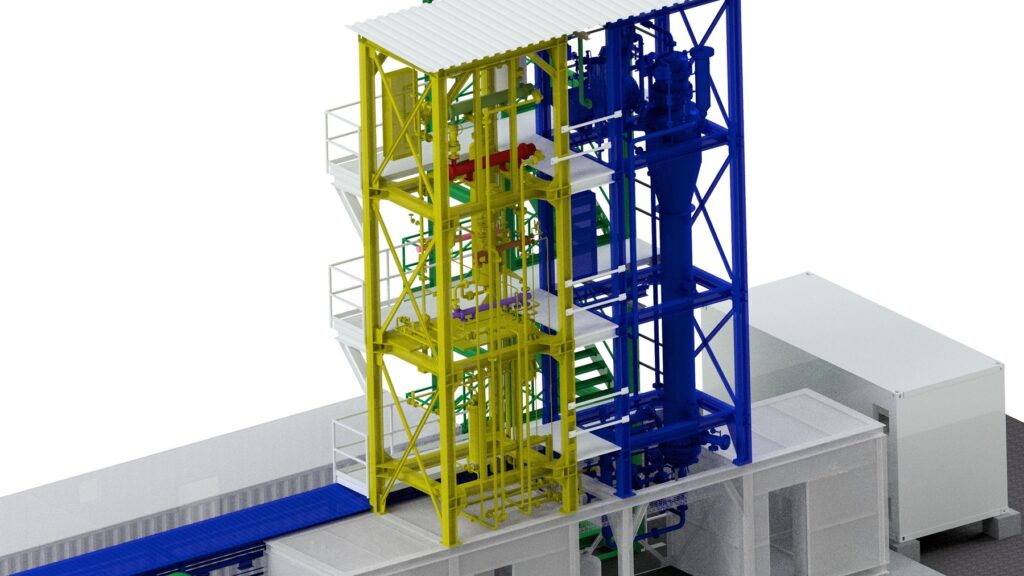

Hydac-Funke has supplied Alpha SYNT with five heat exchangers, which will be installed over the next few months in the dedicated heat-exchanger tower. Their installation represents one of the first visible steps in bringing the HyFuelUp system to life.

At the heart of Work Package 5 (WP5) is the integration of the technology demonstrated in earlier project stages. This involves transforming an existing large-scale gasification unit into a 5 MWth dual fluidised bed gasifier (DFBG, SEG/Oxy-SEG), complete with a methanation unit and an additional hydrogen production unit, together forming demonstrator 3.

Once operational, this integrated facility will produce biomethane at a rate of 37 kg per hour. The gas will then feed into a virtual pipeline system (WP6), including a nano-scale liquefaction unit capable of producing under 10 tonnes of liquefied biomethane (LBM) per day. After liquefaction, the biomethane will be stored in a tank and transported by road to remote sites or end-users.

The implementation of this upgraded facility — located in Tondela (Portugal) and operated by project partner Circle Molecule — will allow the team to validate the full process concept during extended real-world operation.